A zero-to-one enterprise software launch

IBM Supply Chain Intelligence Suite

Modernized supply chain with an improved AI solution, reduced concept-to-MVP timeline by half, and earned industry recognition.

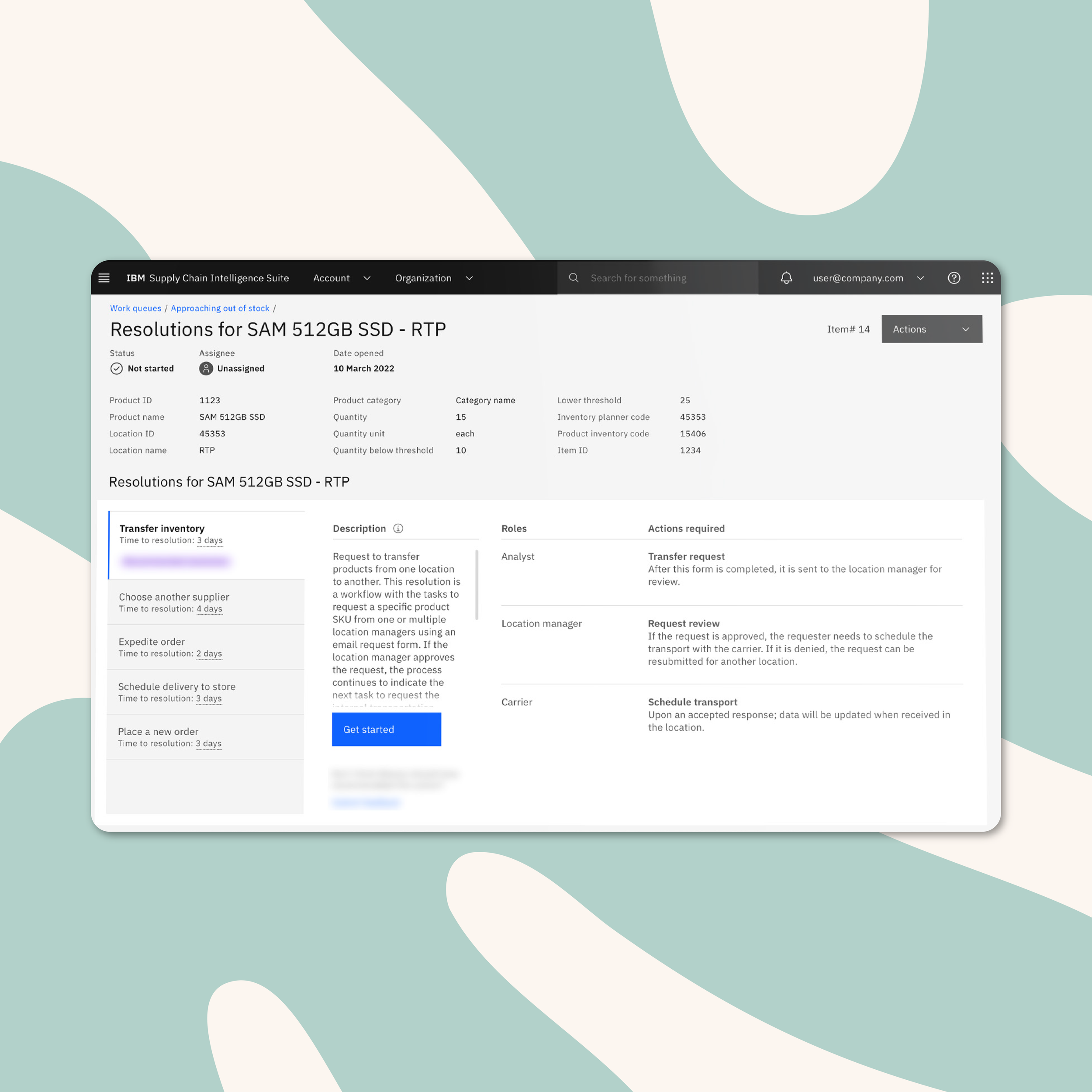

The resolutions page allowed users to monitor critical information and make strategic, real-time decisions to efficiently manage global supply chain disruptions.

Imagine a world where supply chain management isn't just about reacting to problems but anticipating them before they occur. That's the vision behind the IBM Supply Chain Intelligence Suite. This innovative software harnesses the power of artificial intelligence to revolutionize how businesses manage their supply chains, offering predictive insights, smart alerts, and actionable information all in one place.

AI Design, Design Strategy, Design Systems, Cross-Functional Partnerships, Co-Facilitation, UX + Visual Design, Data & Analytics, Innovation with AI

Role: My role consisted of co-facilitating workshops including executive stakeholders and senior level cross-functional leadership team members, rapid prototyping including design and AI ideation, and contributing new components to the Carbon Design System for adoption.

RESULTS

2 months

Delivery of 3-year product visioning prototype

6 months

Successfully launched concept to in-market availability

300+

Customer migrations from legacy platform into new suite at launch

20%

Immediate time savings as measured by usability testing

1

AI Excellence award from the 2022 Business Intelligence Group

CHALLENGE

IBM had made previous attempts at supply chain visibility solutions, but they failed to gain traction. We faced the challenge of not just modernizing these solutions but completely reimagining them to meet the needs of today's businesses.

Our mission was clear: modernize IBM's supply chain management by consolidating existing products and experiences into a unified suite, integrated with cutting-edge AI capabilities. And we had to do it fast—within a matter of months.

align STAKEHOLDERs + identify MARKET FIT + integrate ai + 2 months = SUPPLY CHAIN INTELLIGENCE SUITE

ACTION

Tiger Team* assembled for our Supply Chain Mission.

A small group of experts across Design, Product, Engineering and partner disciplines came together for 8 weeks with a mission to redefine the product strategy for IBM's supply chain offerings—from the ground up.

By centering around an artifact-driven, purposeful collaboration, leveraging foundational design patterns and enterprise design thinking, and leaning hard on the RITE method, our team guided cross-functional leadership to establish a unified vision based on user research and rooted in the needs of the market.

8 WEEKS of

A small team making decisions quickly.

Always be creating:

Creating design artifacts to drive discussion, discovery, and refinement.

Playbacks with stakeholders and testing concepts with supply chain experts.

Time boxing to act quickly to make an impact and identify patterns to streamline.

Original NASA Tiger Team assembled for the Apollo 13 mission.

*Tiger Team: a group of specialists brought together to achieve a specific goal or solve a particular problem. Our team consisted of Product, Engineering, and Design.

The Tiger Team spent the first few weeks digging through existing material from sales enablement, industry research, and conducting countless interviews with PMs and Consulting. **

They wanted a visibility tool — but those already existed in the market.

**During this phase, we found user research that had been all but ignored previously.

“There could be a zillion things you could be looking at, and there are different portals depending on what kind of access you have...”

“[We] usually pull stuff our of the ERP system, run it overnight, they just get a spreadsheet to refresh every day”

so, WE consolidated all of this…

Samples of disparate solutions (email, ERP systems, and spreadsheets) used to find data related to supply chain.

→

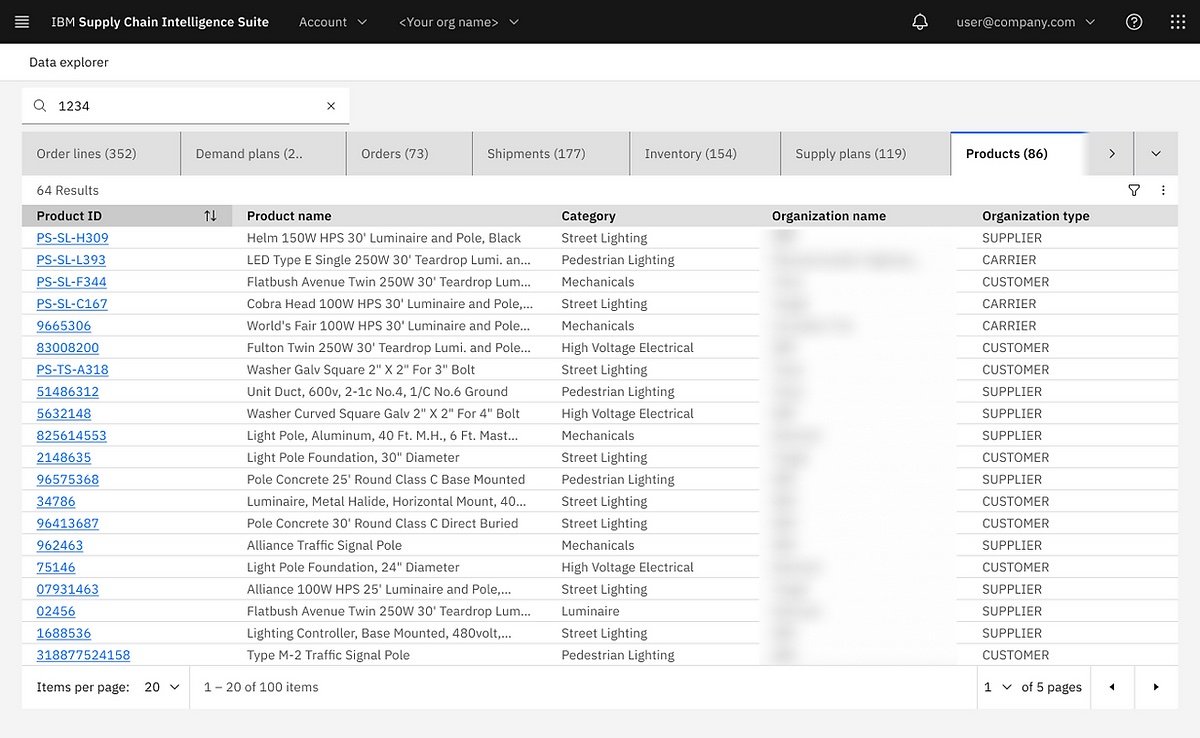

…INTO a single data source.

Disparate data sources consolidated in the Data Explorer.

Following an artifact driven approach meant that we were making prototypes and testing these concepts with users & SMEs on a weekly, sometimes daily, basis.

OUR FINDINGS REVEALED

Extracting meaningful insights is highly challenging.

Users to manually forecast supply and demand by analyzing data from previous cycles.

A significant absence of a centralized information source + Information is not available in real-time.

Inability to predict stock shortages.

Our daily agile collaboration consisted of tangible artifacts to drive discussion and gather insights. We interviewed users and tested our designs, gathered feedback, and continued to iterate.

This discovery led our team to lobby to include AI capabilities as a necessary component of SCIS.

users Need:

Visibility

actionability

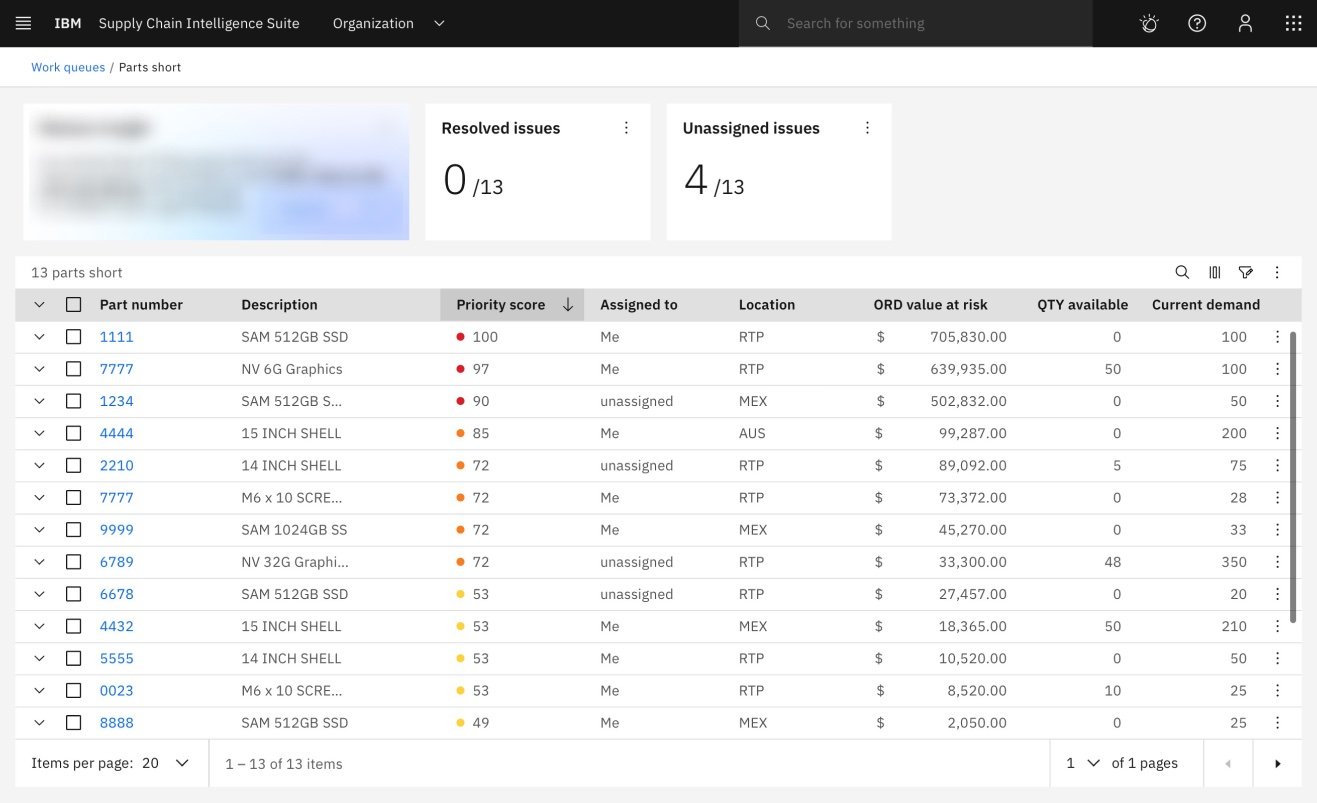

Work queue list showing all queues based on importance and a specific Work Queue showing parts short of demand.

When we showed users "actionability" it started to become apparent which actions they really didn't want to take at all—but would rather automate.

Next, we learned which actions they needed assistance with on a regular basis—assistance that could be provided by AI.

ACTIONABILITY

⬇

AUTOMATION

Work Item Resolution page and an AI powered Work Item Research

In just two months, our team rallied around a prototype that would lay the groundwork for launching the Supply Chain Intelligence Suite, and casting the 3-year vision.

Every team member not only knew the demo inside out but also understood the script and could articulate the vision and its significance.

This prototype served as the guiding star, and empowered the team to craft meticulously detailed requirements, fueling a rapid pace of development.

✨ Along the way, we made sure to keep the teams responsible for building and launching the product engaged through regular playbacks. As the Tiger Team completed its mission, these teams seamlessly picked up the baton and ran with it.

RELEASE highlights

AI-driven resolutions

AI-driven work queues

Data explorer + details

Dashboard

Our high-value MVP designs included work queues, resolutions, data explorer and detail pages, highlighting key information and allowing users to take intelligent action.

The Supply Chain Intelligence Suite didn't just modernize supply chain management; it transformed it.

Our journey from concept to launch was marked by collaboration, innovation, and a relentless focus on delivering value to our customers. The Supply Chain Intelligence Suite is more than just a software solution—it's a game-changer for businesses navigating today's complex supply chains.

sales growth

Scripted prototypes served as a vital sales tool, contributing to SCIS's growth from a single legacy customer to multiple signings in the first months in market.

industry recognition

SCIS earned the 2022 Artificial Intelligence Excellence Award from the Business Intelligence Group for its predictive insights and smart alerts, allowing businesses to proactively address issues before they arose.

influence

Product teams across the business subsequently followed this Tiger Team approach sparking a wave of innovation across the company, and influencing teams to iterate and launch their own new concepts.

© All images, UIs, and information copyright International Business Machines Corp.

Learn more about IBM Supply Chain Intelligence Suite, here.